- Sustainability

- Message from CEO

Message from CEO

As Team NLM, we will strive to be a groundbreaking innovator of aluminum and beyond.

We will seriously work on our tasks one by one as a team.

Review of the past year

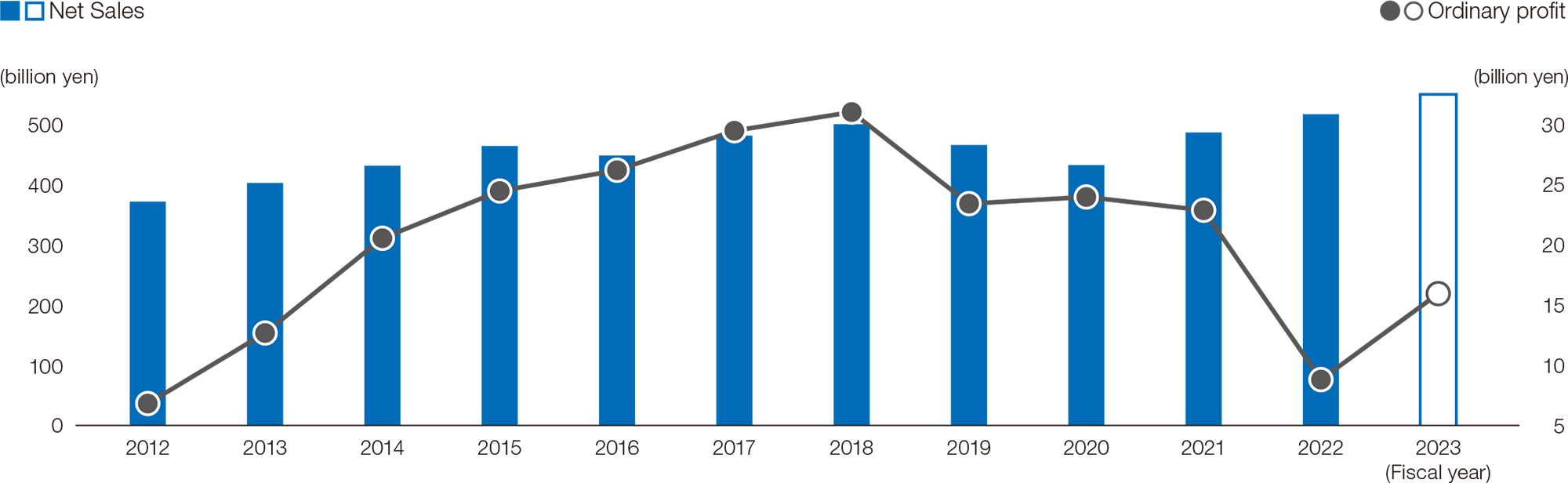

First, I would like to summarize the Group’s business results for last year and describe our future outlook. The consolidated financial results of the NLM Group have remained steady since 2012, when we adopted a holding company structure, with ordinary profit having exceeded 30.0 billion yen in FY2018, for example.

Last fiscal year, however, while net sales grew 6.2% year on year, to 517.0 billion yen due to revisions to the sales prices that reflected aluminum ingot market conditions and raw material and fuel prices, ordinary profit stood at 8.9 billion yen, down61.4% year on year, falling short of the target, mainly reflecting a decrease in sales attributed to sluggish automobile-related demand caused by semiconductor shortages, and delays in truck chassis supply, as well as higher costs that resulted from a surge in prices of aluminum and other raw materials, materials, and fuel, among other factors.

At present, we are pursuing initiatives to achieve a recovery in our business performance, such as continuing to accelerate overseas expansion and stepping up efforts to create new businesses and products, as well as passing higher raw material and fuel prices on to sales prices appropriately.

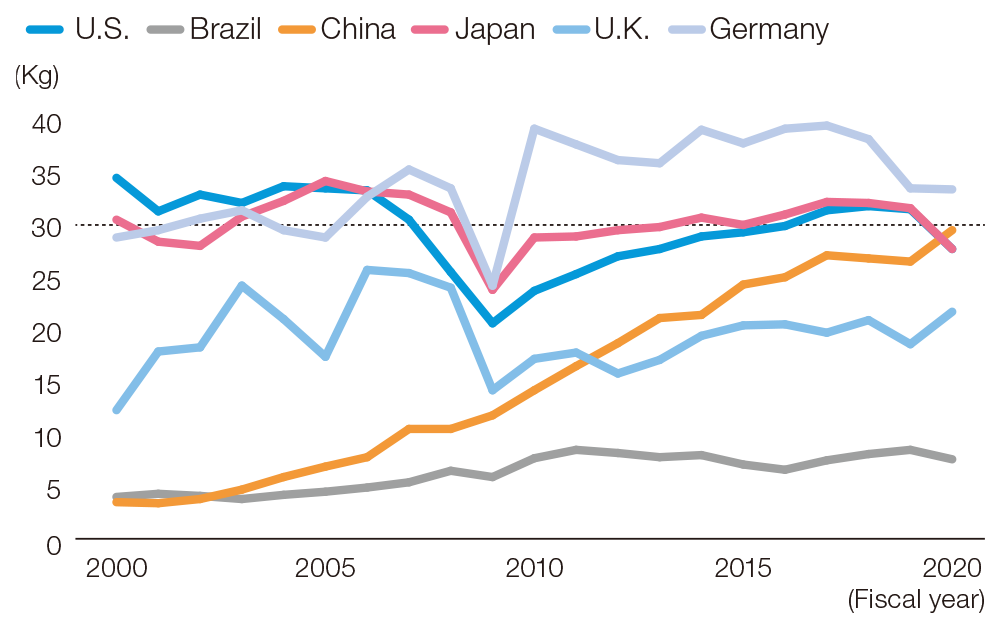

Per-capita Demand for Aluminum

*Source: Data from the Japan Aluminum Association

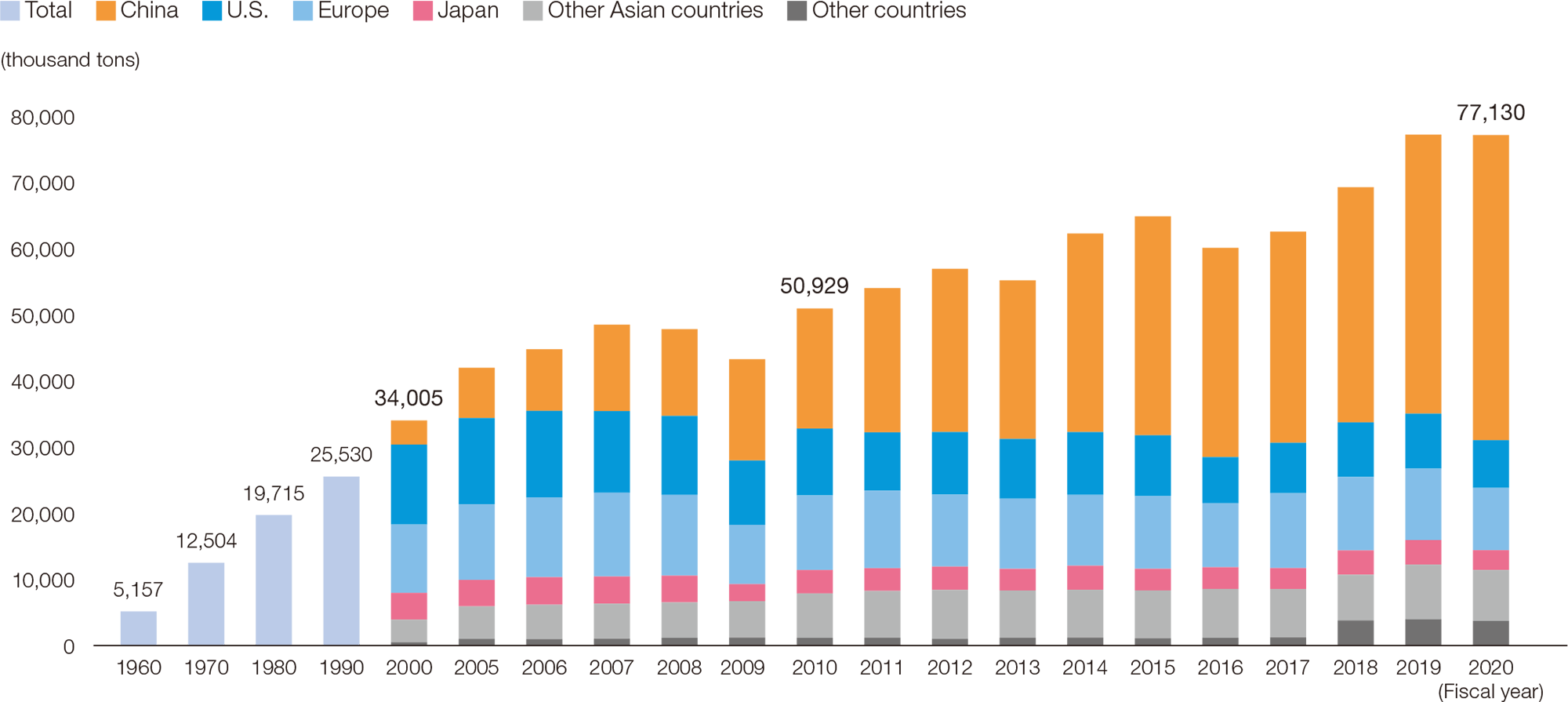

In the meantime, the demand for aluminum in Japan has remained almost flat since 2000. The ratio of demand for aluminum in Japan to that in the global market is approximately 5%, with an annual amount of around 4 million tons. Even in China, the only country where quantitative expansion has taken place, the annual per-capita consumption of aluminum is approaching 30 kilograms, which is regarded as the global average consumption, in recent years.

We believe that an increase in aluminum consumption to a much higher level is as unlikely in China as it is in Japan, Europe, and the United States. While the quantitative expansion of aluminum based on high-volume production and consumption now approaching its limit, what we should dedicate ourselves to is simply the development of new applications and the creation of what is perceived as value for customers. I believe it is important to provide products and services needed by customers by leveraging the strengths of the NLM Group.

Consolidated Financial Results

Changes in Demand for Aluminum in the World

*Source: Data from the Japan Aluminum Association

Results of investigations into the quality-related misconduct incidents and prevention of recurrence

Before explaining the NLM Group’s Management Policy and management measures, I want to take this opportunity to sincerely apologize once again for, and report the progress of measures on, the revocation of JIS certification and request that we cease the use of the JIS mark (quality problem), which has caused you inconvenience and concern.

I will start by explaining the investigation report from the Special Investigation Committee consisting of external experts and other members. Because the scope of the investigations was expanded to business sites other than JIS-certified sites, the investigation period was long, at one year and nine months. The investigations were completed in March this year, and we received the investigation report. While the investigations by the Special Investigation Committee were ongoing, we ourselves held repeated discussions on structural factors behind the incidents and initiatives to prevent any recurrence. While taking the investigation results from the committee seriously, we have adopted measures to prevent any recurrence of the problems, aiming to become a corporate group that is trusted by its stakeholders.

As initiatives to prevent a recurrence, we will advance management reforms, including rebuilding the Group’s governance structure, and will reinforce internal control functions such as reforming our corporate culture.

A workplace visit

In particular, our corporate culture took a long time to take root in the NLM Group. I understand that it cannot be changed overnight.

To fully communicate the ideas of management to employees working on the front lines and to permit direct dialogue between management and employees, we launched site manager meetings and workplace visits in April this year. For the site manager meetings, we have divided each workplace of the NLM Group into teams of roughly 20 members and appointed the teams’ representatives as site managers. We convene the site manager meeting each month with the participation of around 400 site managers. Agenda items discussed in the meeting include Group-wide management issues, such as causes of quality problems and measures to prevent their recurrence. After a meeting, each one of the 400 site managers gives explanations to 20 members of their workplace. Thus, we attempt to have ideas of the management and details of our initiatives shared by a total of about 8,000 Group employees in Japan. In workplace visits, I myself as the leader of the management team visit plants, branches, offices, and other workplaces and hold talks with about 20 employees each. I tell them what management is thinking while employees tell me about the problems they face in working, issues in their workplaces, and other matters as the opinions of people working on the front lines. As in the site manager meetings, I will talk directly with all employees through a total of 400 workplace visits, speaking with 20 people per visit. In this context, at one workplace that I visited, employees working in a plant voiced an opinion, “We want to introduce a day when we stop all equipment for around 30 minutes and talk about quality in each workplace.” I agreed with them, saying “That sounds good. Let’s do it.” Thus, it was decided that the plant will introduce its own Quality Day. Having witnessed the moment when each employee treated the quality problem as their own issue and their fire was lit, I feel this is exactly what I am responsible for making happen.

Moreover, in April 2023, the NLM Group Business Conduct Guideline was formulated, with the leading role played by 36 young and mid-career employees from 16 Group companies. This was determined and approved through presentations by the representative of the employees, which were given directly to the Group Executive Committee, the Board of Directors, and others. Thus, the NLM Group Business Conduct Guideline very much reflects the thoughts of the NLM Group and the 36 project members. Ifan event going against the Business Conduct Guideline should occur in the future, they will point it out and say with a loud voice, “That’s against the principle.” I regard these activities as epitomizing Sottaku Doji*1. I am seeing signs of our evolving into a corporate group where everyone can express their opinions more freely than ever. Reforming corporate culture is a never-ending process. I will continue to light each employee’s fire.

*1 Sottaku Doji:It means that the activities of master and pupil conform with each other.

Working as one to achieve the 2023 mid-term management plan

Our thoughts reflected in new Team NLM

Reflecting the changes in our business environment and initiatives to prevent a recurrence of the quality problem, we reviewed the 2022mid-term management plan this fiscal year, or one year after its launch, and adopted the 2023 mid-term management plan, under which the NLM Group will make a fresh start as new Team NLM. The 2023 mid-term management plan is also an expression of our determination as we make a fresh start as new Team NLM. The word “new” in new Team NLM conveys the meaning that we will be reborn and achieve a recovery of social trust and earnings. Initiatives for new Team NLM constitute one of the pillars of the management policy under the 2023 mid-term management plan in the aspects of both offense and defense.

Even with new Team NLM, however, the fact remains that people and organizations work together organically within the Group, we demonstrate the Group’s comprehensive capability by leveraging the combined wisdom of individuals, and we continue to create new value for customers. We will work consistently to attain our targets.

Our thoughts reflected in new Team NLM

One of the initiatives for new Team NLM is to promote management reforms and reinforce internal control functions. As a leader of the management team, I will work on the reform of our corporate culture by continuing the site manager meetings and workplace visits that I mentioned above. Meanwhile, reviewing the NLM Group’s structure once again, I noted that 69 of the total 78 Group companies have 300 or fewer employees each, and that 42% of all Group employees belong to these companies. This means that the NLM Group includes many small and midsize subsidiaries. We are planning to rebuild the Group’s governance structure by bundling these small and medium enterprises into some what larger groups and managing those groups.

Establishment of Nikkeikin ALMO

If the above is about the aspect of defense, such as reforms of corporate culture and rebuilding of the governance structure, an example of our more proactive measures is the establishment of Nikkeikin Aluminum for Mobility Company, Ltd. (Nikkeikin ALMO). We have integrated our automotive components businesses, which had been divided based on manufacturing methods and operated by Group companies, into a single corporate organization, aiming to facilitate the consolidation of dispersed management resources and their flexible allocation. The automotive market, where actions for carbon neutrality and electrification are underway, has diverse potential, for instance in materials and manufacturing methods. We can therefore expect major business opportunities for the NLM Group.The automotive market, where actions for carbon neutrality and electrification are underway, has diverse potential, for instance in materials and manufacturing methods. We can therefore expect major business opportunities for the NLM Group. The strengths of the Group lie in the fact that we have comprehensive capabilities, ranging from manufacturing methods and processing technologies, such as casting, processing, and bonding, to development, design, maintenance, and services, which are based on our comprehensive knowledge about material properties. I believe that by consolidating these strengths, we can provide the products and services demanded by customers along with high added value.

Toward the realization of sustainable management

At the NLM Group, we are forging ahead with sustainable management under the Corporate Philosophy: Contribute to improving people’s quality of life and environmental protection by continuing to create business, focused on aluminum.

In this context, we have set the following five themes as our priority issues (material issues) to address to enable the NLM Group to achieve sustainable growth and to enhance its corporate value.

- Protecting the global environment

- Providing sustainable value

- Happiness of employees

- Responsible procurement, production and supply

- Corporate ethics and governance

Driving carbon neutrality

Driving carbon neutrality is one of the important tasks of new Team NLM for protecting the global environment and providing sustainable value. Because of our historical context, we have diverse business segments, from upstream to downstream. It is true that it was difficult for the Group to drive carbon neutrality optimally only with the plans and measures of the individual business segments. In response, we have established the Green Growth Strategy Office as an entity that plans and drives the integrated decarbonization strategy of the Group. This is a new challenge that we are taking on to manage risks and opportunities in our decarbonization strategy with an integrated approach, aiming to achieving net zero greenhouse gas emissions by FY2050.

Generally, among the processes of manufacturing new aluminum ingots, a large amount of electricity is consumed when aluminum as a metal is taken from the raw material, leading to an idea that the manufacturing process emits a great deal of CO2. From the viewpoint of the entire lifecycle, however, aluminum contributes to reducing CO2 emissions because this material is expected to improve energy efficiency while it is used, such as by reducing the weight of automobiles and other products. In addition, aluminum also features superior recyclability. At the same time, the CO2 burden of recycled ingots is one-tenth that of new aluminum ingots. We therefore believe that we can make a major contribution to future decarbonization through recycling.

At the NLM Group, horizontal recycling of aluminum for expanded materials, which is the major application of new aluminum ingots, is an important means of decarbonization and carbon reduction. On the other hand, to use scrap from the market directly for expanded materials, it is essential to establish a technology for sorting out and separating from scrap only that portion that is equivalent to the portion of new aluminum ingots for expanded materials. We aim to establish, and find practical application of, the technology by harnessing the knowledge of Nikkei MC Aluminium Co., Ltd., which has been engaged in the recycling business at the Group for many years. To do this, we have integrated the functions for procurement, production, and sales of materials for expanded materials into a new Metal Business Division, thus establishing a framework for implementing measures such as enhancing procurement of low-carbon materials, expanding the use of scrap from products we produced, and building closed-loop supply chains with customers.

We will also work to improve our upgrading technology by leveraging aluminum material technologies as our strength, thus contributing to not only expanding the Group’s business but also protecting the global environment and providing sustainable value.

Helping build a sustainable society with the happiness of employees as the driving force

I believe that, among the priority issues of the NLM Group, what serves as the engine of sustainable management is the happiness of employees. I understand that it is only when each of our employees feels pleasure and job satisfaction and can work daily with pride in being a member of the NLM Group that initiatives to address each issue make progress and targets, including the KPIs, are achieved. As one initiative for this purpose, we have become an official partner of Japan’s national wheelchair rugby team and engage in a number of activities. Five young employees of the Group are playing the leading role in this initiative. They are widening the circle of activities, such as participating in events to support the Japan’s national team when they play and in the operation of games as volunteers. Further, at Tomakomai Complex of Nippon Light Metal Co., Ltd., we have renovated Nikkei Arena, a gymnasium, as part of our initiatives to improve the work environment. In the renovation, the entire building, including pathways and locker rooms, were designed to be barrier-free. We are also proactive in offering the space for external teams. At present, it is widely known as a hub of parasports activities, where people can take part in wheelchair rugby, wheelchair basketball, and other parasports. I believe that these social contribution activities will give employees working together the pleasure of and pride in serving society as corporate citizens and lead to the happiness of employees, and ultimately, to the recovery of social trust in the Group, improvements in its earning power, and its sustainable growth.

In Closing

I think that the task with top priority for enabling the Group to achieve sustainable growth is to recover social trust. Improving earnings strength is built upon social trust.

What is important for this purpose is that each member of the management team and each employee should be proud of being a member of the new Team NLM and should find it rewarding and enjoyable to work for the NLM Group.

As a major duty to fulfill for this purpose, I will continue to light people’s fire through site manager meetings and workplace visits.

We will continue our efforts to be a groundbreaking innovator of aluminum and beyond, so as to recover your trust and fulfill your expectations.